SuperPros vertical pivoting bushes provide a perfect example of how replacing or upgrading a standard rubber component with a polyurethane equivalent can provide a series of significant benefits. Especially those found in modern-design suspension systems and specifically, the front control arms.

The VPB design means that all articulation of the suspension is achieved by the flexing of the rubber bush, which inevitably causes distortion, especially under high lateral loads as the rubber tries hard not to tear itself apart. This results in cornering forces and the condition of the road surface moving the front wheels without any driver input and consequently, a momentary misalignment of steering geometry. This can cause vague steering, increased torque-steer and uneven tyre wear.

To overcome these issues, SuperPro began developing a VPB replacement as long ago as 1994 for the Ford Escort Mk3. However, it was not just a case of copying the original rubber components in polyurethane, as this would only replicate many of the issues. Therefore, something more innovative would be required to ensure the control arm would articulate freely, last longer and not increase NVH. The result was a sophisticated yet simple solution.

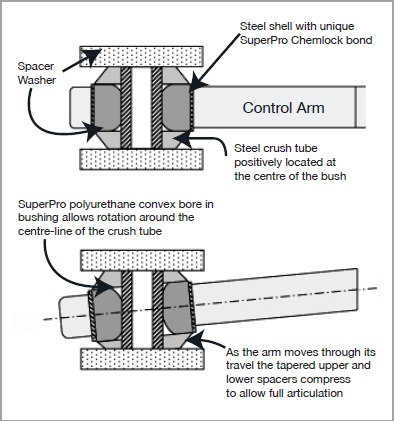

Each SuperPro VPB is an assembly of four components: a steel encased outer bush that presses into the control arm; a steel tube that fits tightly into the centre of the bush, leaving a chamfered gap at each end to allow movement; and two polyurethane cones that fit neatly over the ends of the extended inner tube. This unique assembly allows the control arm to pivot in the vertical plane with minimal resistance, whist retain positive location in the horizontal plane.

This ensures that all steering loads and suspension movements are directed to the wheels. The positively located joint means the suspension geometry remains consistent and consequently, this provides excellent feedback and feel through the steering, reduced torquesteer and even tyre wear. And, because a SuperPro equipped arm will pivot freely without the material needing to flex to achieve movement - plus, with the long-lasting properties of SuperPros unique blend of polyurethane - a high level of performance can sustained for most of the vehicles life.

SuperPros vertical pivoting bushes provide a perfect example of how replacing or upgrading - a standard rubber component with a polyurethane equivalent can provide a series of significant benefits, especially those found in modern-design suspension systems and specifically, the front control arms.

The increase in manufacturers using sub-frame assemblies where the undercarriage, engine and transmission units are fitted from underneath the car, has led to a change in design of the front control arm bushes, which has in turn uncovered issues with the performance and longevity of the standard-fit rubber bushes. Consequently, most workshops are likely to be familiar with the ever-increasing need to replace front control arms as a result of excessive wear and the failings of the rubber components.

Whereas the traditional mounting of both control arm joints was by using a bolt or pin located in a horizontal plane - in an attempt to reduce production-line assembly times - recent designs have seen the use of vertical pivoting bushing (VPB). This allows the bolt or pin in one of the joints to be located in a vertical position, whilst the other often remains horizontal. The shape of the arm and the way in which a VPB functions has led to a significant change in the design of rubber bushes for this purpose, with manufacturers introducing segmented or directional shapes and introducing voids to allow more movement and reduce NVH (noise, vibration and harshness).

Click here to get a print version of the VPB Bulletin.